Description

Description

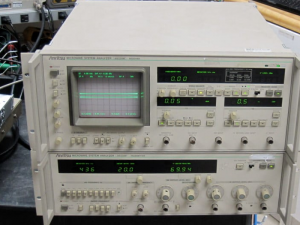

Fitel S175 Fusion Splicer is a complete package offered in a custom made carrying case.

The Fitel S175 is a direct core monitoring fusion splicer. The splicer automatically analyzes the fiber type from single mode (SM), multi mode (MM) and dispersion shifted (DS) and loads the suitable splice program. The Fitel S175 from Furukawa is made to splice silica glass-based optical fibers SMF, MMF, DSF and EDF (erium doped fiber). It can splice 0.25 to 0.9 mm coating and 0.1 to 0.15mm cladding. Single mode fiber can be spliced in as little as 20 seconds.

We wanted a better explanation and this is what we found

An instrument that splices fibers by fusing or welding them, typically by electrical arc.

The process of fusion splicing involves using localized heat to melt or fuse the ends of two optical fibers together. The splicing process begins by preparing each fiber end for fusion. Fusion splicing requires that all protective coatings be removed from the ends of each fiber. The fiber is then cleaved using the score-and-break method. The quality of each fiber end is inspected using a microscope. In fusion splicing, splice loss is a direct function of the angles and quality of the two fiber-end faces.

The basic fusion splicing apparatus consists of two fixtures on which the fibers are mounted and two electrodes. inspection microscope assists in the placement of the prepared fiber ends into a fusion-splicing apparatus. The fibers are placed into the apparatus, aligned, and then fused together. Initially, fusion splicing used nichrome wire as the heating element to melt or fuse fibers together. New fusion-splicing techniques have replaced the nichrome wire with carbon dioxide (CO2) lasers, electric arcs, or gas flames to heat the fiber ends, causing them to fuse together. The small size of the fusion splice and the development of automated fusion-splicing machines have made electric arc fusion (arc fusion) one of the most popular splicing techniques in commercial applications.