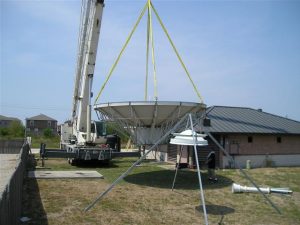

Teleport Facility Large Satellite Earth Station Dish Removal

When we refurbish a full satellite antenna, including king post or support we have a detailed process leading to the finished product.

If the antenna is sold within the US we normally contract to re-install it, but in cases where the antenna is being sold overseas we take a few extra steps of photographing the existing antenna prior to take down so that we can email photographs and video to the installation team.

Take Down

- Antenna is photographed in place, with attention paid to the location and attachment of radials and panels

- Disassembly begins, with each stage photographed, or in some cases video is shot.

- Panels, radials and panel supports are grouped together and secured before loading onto our flatbed.

- Antenna bushings are examined and discarded if excessive wear is found.

Inspection

- All moving hardware is examined for excessive wear with replacement parts ordered if necessary

- Motors are sent for electrical testing and if necessary they are refurbished.

- Damaged or missing assembly hardware is examined and replaced if needed.

- Jack screw boots are replaced if needed

Refurbishing

- Rusted areas are sanded and stripped

- Antenna is pressure washed

- The antenna is sprayed with coats of primer

- The final coats of acrylic paint are applied to the antenna

- Rusted galvanized parts are sent for re-galvanizing

Packing for Shipment

- Where appropriate the foundation bolt kit is ordered and shipped separately to the client

- The completed antenna is loaded into the clients shipping container

- If needed racks or supports are built within the shipping container to ensure damage free transportation

- The loading process is photographed and all parts identified

Teleport Facility Large Satellite Earth Station

Installation

- Once the civil work is complete and the new pad is ready to receive the antenna the container is set down at the new site

- The foundation bolts on the pad are examined and measured for accurate placement

- The king post or antenna support structure is unloaded and made ready for installation with the crane

- If the site is secure the panels, radials and supports are unloaded and the reflector is built on the ground

- When needed the radials are aligned with a theodolite

- A rented crane is delivered to the site and the king post and completed reflector are installed.

- Using a theodolite the reflector is shot to manufacturers specifications

- Where appropriate the sub-reflector is placed on the antenna.

- Cables are pulled for the SSPA and LNA and Antenna Controller package

Testing and Certification

- Electrical connections are completed and the antenna controller and full range of motion is verified.

- Motors are tested for low speed and high speed operation.

- Working with the client’s choice of satellite, patterns are run and verification received from the operator’s NOC.

- We guarantee that the transmit gain will be to within 1dB of original factory specification.

- Demonstration that the antenna controller system is working correctly.

- The antenna will pass two degree compliancy requirements.

Teleport Facility Large Earth Station Dish Remal Picture 4

Teleport Facility Large Satellite Earth Station Dish Removal Picture 5

Teleport Facility Large Satellite Earth Station Removal Picture 6

Teleport Facility Large Satellite Earth Station Removal Picture 7

Teleport Facility Large Satellite Earth Station Removal Picture 8

Teleport Facility Large Satellite Earth Station Removal Picture 9

Teleport Facility Large Satellite Earth Station Dish Removal Picture 10

Teleport Facility Large Satellite Earth Station Dish Removal Picture 11